Welding plays a vital yet often overlooked role in modern industry. From the towering steel skeletons of bridges to the complex chambers of a ship’s hull, welding is the unseen force that binds the built world together. As manufacturing evolves, so too does the art and science of welding—driven by demands for precision, flexibility, and safety.

Welding is essential to the structural integrity, durability, and safety of modern industrial products—from bridges and ships to pipelines and machinery. In high-performance sectors, weld quality directly impacts reliability and compliance. As manufacturing shifts toward automation and flexibility, welding must meet higher standards of precision, consistency, and adaptability. It is no longer just a fabrication step, but a critical enabler of industrial innovation.

1. Shipbuilding: High-Risk Precision in Tight Spaces

Ship construction presents some of the most extreme challenges in welding. Confined compartments, complex curved surfaces, and varied welding positions—such as overhead and vertical welds—require high stability and consistent accuracy. Today, magnetically mounted welding systems allow 360° multi-directional operation even on curved or inclined surfaces, enabling safer and more efficient execution in tight shipboard environments.

DOBOT Welding Solution in Shipbuilding

2. Bridge and Infrastructure Projects: Strength Meets Portability

In large-scale infrastructure projects, welds must withstand decades of mechanical stress and environmental exposure. Portable welding robots, optimized for compactness and precision, are now deployed directly on-site. Mounted on tracks or gantries, these systems navigate complex paths and deliver sub-millimeter accuracy—even when working on high-altitude bridge segments—ensuring both safety and build quality.

DOBOT Weld in Bridge Steel Structure: Enabling Precision at Scale

3. Container Manufacturing: Scaling with Zero-Defect Standards

Mass production of shipping containers demands a high level of repeatability and speed. Robotic welding systems equipped with intelligent path planning and high-precision control help manufacturers maintain “zero-defect” standards. These systems ensure consistent weld seams across thousands of units, while keeping production rates high and rework costs low.

1. Medical Device Manufacturing

Medical welding requires high precision and cleanliness, especially in stainless steel components and delicate assemblies. Robotic systems on sliding tracks enable multi-station workflows, allowing a single robot to switch between tasks with minimal downtime—boosting throughput and consistency in compact manufacturing cells.

DDOBOT Cobot Integrated with Slide Rail

2. Construction and Steel Structures

Irregular geometries and non-standard joints are common in architectural and structural steel. Robotic welders with magnetic mounting systems can attach to complex surfaces and adapt to different orientations. Paired with mobile guide rails, they offer flexible deployment across large or multi-tiered frameworks.

DOBOT Welding Solution in Construction & Steel Structure

3. Heavy Machinery and Equipment

For large, load-bearing machinery, weld strength and penetration are critical. Oscillating weave patterns and multi-layer welding functions help expand weld width and ensure joint integrity, even in thick materials—supporting high-performance requirements with minimal manual intervention.

Bed Frame Structures Welding with DOBOT CR10

4. Pipelines and Thin-Walled Tubes

Thin-walled components pose challenges such as overheating and deformation. Precision control of arc timing, current, and heat input enables effective welds without burn-through. Automated positioning also helps compensate for minor misalignments and shape variations.

Thin-Walled Pipe Welding with DOBOT Cobot

5. Circular and Angular Components

Round and angular parts benefit from auto-generated welding paths that reduce programming effort. For thick-angle joints, robots can perform multi-pass layering, ensuring deep penetration and strong bonding in high-stress areas.

Corner Joint Welding with DOBOT Cobot

6. Box-Type Structures and Enclosures

With their variable shapes and sizes, box structures require adaptable welding solutions. Intelligent control systems adjust in real time to fit diverse geometries, making them ideal for sectors such as energy, transportation, and electronics.

Box-Type Structures Welding with DOBOT Cobot

As industries evolve toward high-mix, low-volume production, welding is no longer a fixed station on the assembly line—it must adapt in real time to shifting designs, materials, and batch sizes. The rise of flexible manufacturing demands systems that are not only accurate, but also reconfigurable, mobile, and smart.

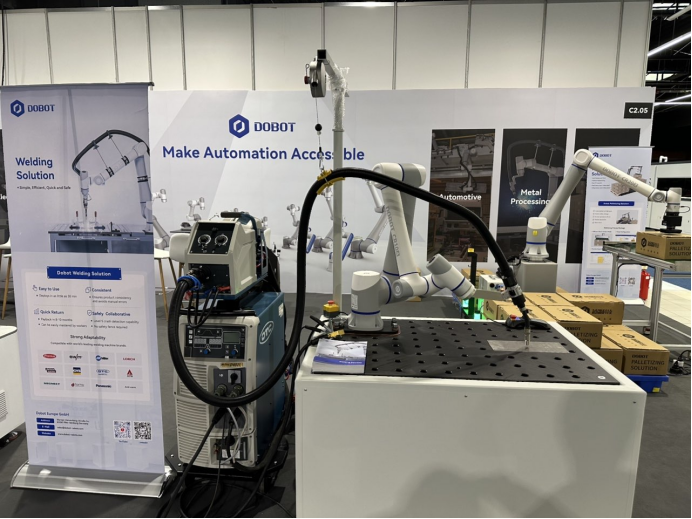

Advanced welding technologies—such as multi-axis robots, intelligent process packages, and adaptive control systems—are making this transition possible. These solutions reduce reliance on manual expertise, lower operational risks, and unlock new possibilities in environments where traditional automation struggled to perform.

Ultimately, welding is becoming a strategic asset in smart factories. It enables manufacturers to maintain high standards while embracing customization and agility—two key pillars of the next industrial era.